In the intricate world of industrial electronics and repair, the seamless operation of machinery often hinges on a single, critical component: the human-machine interface. For countless devices powered by SHARP microprocessors, this vital link is frequently the

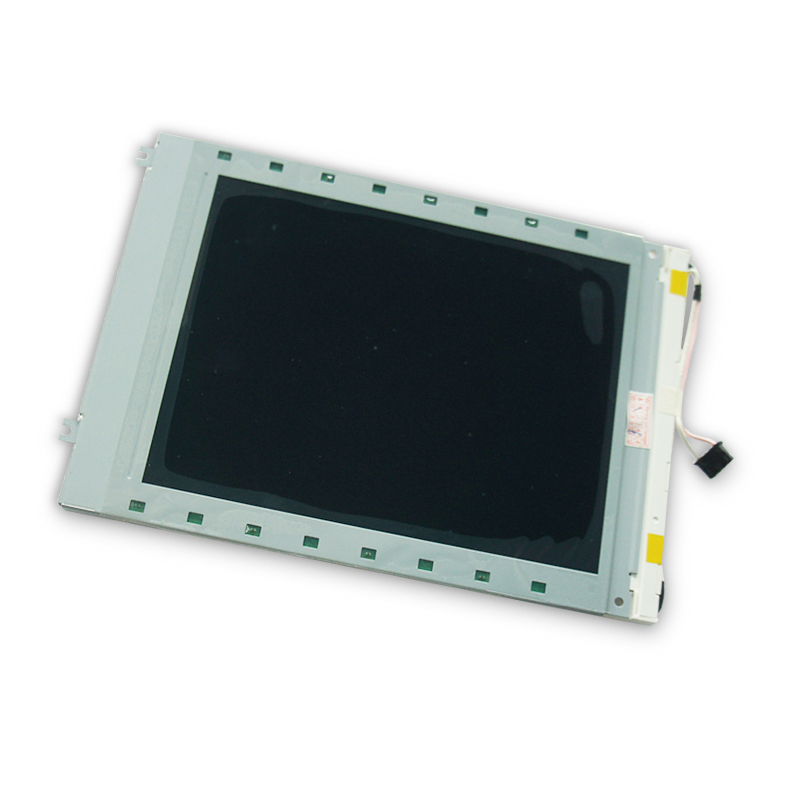

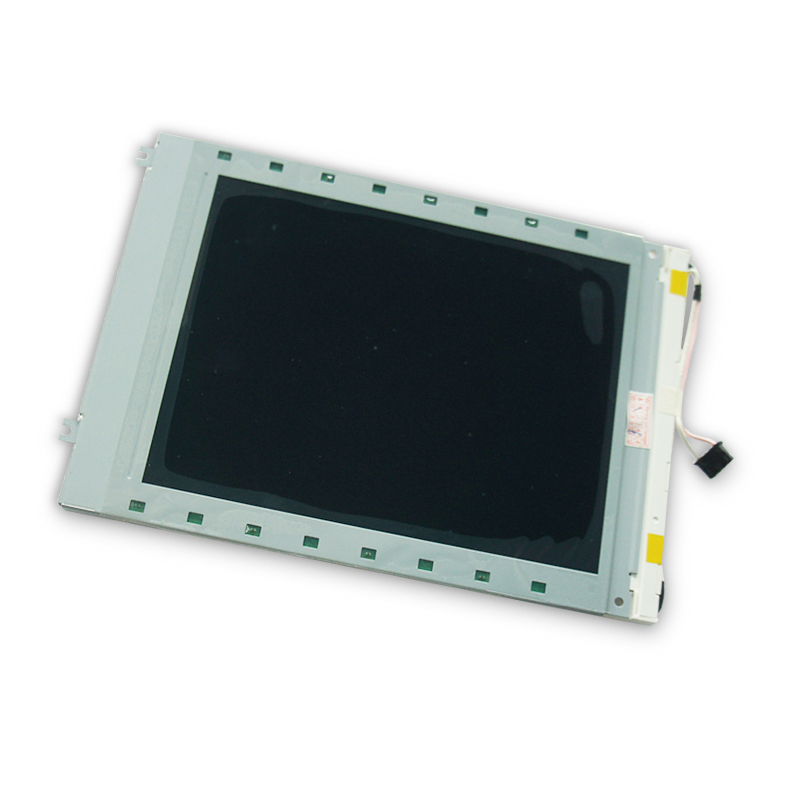

LM64P101 LCD display module. More than just a simple screen, the

is a specialized, integrated solution designed to communicate directly with SHARP's LH and LH series of 4-bit microcontrollers, such as the ubiquitous LH5160. This article delves deep into the

LM64P101, exploring its technical architecture, unique role within SHARP's ecosystem, and its enduring significance in maintaining legacy systems.

Understanding this module is crucial for engineers, technicians, and procurement specialists. It represents a bridge between proprietary hardware design and the practical needs of display functionality. We will unpack its specifications, decode its pinout and communication protocol, and examine its typical applications. Furthermore, we will address the modern challenges of sourcing and replacing this legacy component, providing a comprehensive guide for anyone whose work depends on the reliable performance of SHARP-based equipment. This exploration is not merely about a display; it's about sustaining the lifecycle of critical technology.

Technical Architecture and Core Specifications

The LM64P101 is a controller-less LCD graphic display module, a defining characteristic that shapes its application. Unlike modern displays with integrated controllers like the KS0108, the LM64P101 relies entirely on the host SHARP microcontroller to drive its pixels. It typically features a 128x64 pixel resolution, providing a monochrome graphical canvas for data visualization, simple graphics, or multi-line text. The module includes the glass LCD panel, a conductive elastomer connector (zebra strip), and a PCB with the necessary driver electronics and backlight circuitry, often electroluminescent (EL) or LED-based.

Its core specification is its direct compatibility with SHARP's CPU architecture. The display is mapped directly into the microcontroller's memory space. This means the CPU writes display data not through a serial or parallel command interface, but by writing to specific memory addresses that correspond to segments of the LCD. This tight integration allows for very efficient data transfer but also creates a strong vendor lock-in, making the LM64P101 inseparable from its intended SHARP host. Understanding this memory-mapped I/O is fundamental to programming and troubleshooting.

The SHARP Ecosystem and Proprietary Interface

The LM64P101 exists firmly within SHARP's proprietary hardware ecosystem. It is designed explicitly to interface with microcontrollers like the LH5160, LH5164, LH5264, and similar. These CPUs include on-chip LCD driver circuits capable of directly supplying the segment and common signals required by the display. The physical connection is usually made via a direct solder connection or a dedicated connector, carrying multiplexed LCD drive signals, power for the panel, and backlight power.

This proprietary relationship is a double-edged sword. On one hand, it simplifies system design by reducing component count and firmware complexity for the original manufacturer. The developer works with a unified memory map. On the other hand, for repair and reverse engineering, it creates a significant challenge. The module cannot be easily replaced with a generic 128x64 display without substantial hardware and software redesign. This interdependence underscores the LM64P101's role as a system-specific component rather than a commodity part.

Pinout and Communication Protocol Decoded

While the exact pinout can vary slightly by manufacturer and revision, the LM64P101 interface generally consists of power pins (VCC, VSS, and often a negative voltage for contrast, VEE or VLCD), backlight power (EL+/- or LED+/-), and the critical LCD drive signals. These signals are not standard data/control lines like RS, RW, E, or D0-D7. Instead, they are named as COM (Common) and SEG (Segment) lines, reflecting the direct drive method.

The communication protocol is dictated by the SHARP CPU's internal LCD driver. The CPU continuously cycles through the COM lines, while activating the appropriate SEG lines to light the desired pixels, a process known as multiplexing. The "data" is simply the bit pattern in the CPU's dedicated LCD display RAM area. There is no "send command" to set coordinates; the firmware calculates the memory address corresponding to a specific pixel on the screen. This low-level control offers flexibility but requires deep understanding of the hardware mapping.

Typical Applications and Legacy System Context

The LM64P101 found its home in a wide array of industrial, medical, and commercial equipment from the 1990s and early 2000s. Common applications include programmable logic controller (PLC) operator panels, diagnostic equipment, older point-of-sale systems, specialized test and measurement instruments, and embedded control systems for industrial machinery. Its reliability and clear graphical display made it a preferred choice for environments where simple, stable user feedback was essential.

These systems were often designed for long lifecycles, measured in decades rather than years. Consequently, the LM64P101 is today primarily encountered in a maintenance, repair, and overhaul (MRO) context. Technicians are not designing it into new products but are tasked with keeping legacy systems operational. This shifts the focus from development to sourcing, compatibility verification, and physical replacement techniques, often with limited documentation available.

Sourcing Challenges and Authenticity Verification

As a discontinued component, sourcing the LM64P101 presents significant hurdles. Original stock from SHARP or authorized distributors is scarce. The market is largely supplied by third-party manufacturers, surplus dealers, and salvaged parts. This landscape is rife with risks: incompatible revisions, poor-quality glass or backlights, and outright counterfeit modules. A module labeled LM64P101 may have subtle differences in pinout, contrast voltage requirement, or physical dimensions that can cause system failure.

Verification is multi-faceted. Technicians must cross-reference the exact part number (including any suffix), physically measure the module and pin spacing, check the voltage requirements against the host system's schematic, and if possible, test functionality before full installation. Purchasing from reputable suppliers with clear photographs and technical support is critical. Understanding that "LM64P101" is a generic descriptor for a type of display, not a guarantee of absolute compatibility, is a key lesson in legacy component sourcing.

Modern Alternatives and Replacement Strategies

When a genuine or compatible LM64P101 cannot be sourced, engineers must consider replacement strategies. The most common modern alternative is to use a standard graphic LCD module with a controller (e.g., based on the ST7920 or KS0108) and a microcontroller board (like an Arduino or STM32) to act as a protocol translator or "emulator." This intermediary board would read the legacy system's COM/SEG signals, interpret the display data, and redraw it on the new screen via a standard parallel or serial interface.

This is a non-trivial engineering task requiring signal analysis, firmware development, and custom PCB design. However, it offers a long-term solution and can upgrade the display to higher contrast or LED backlighting. A less invasive strategy is to seek a "drop-in replacement" from specialized vendors who produce newly manufactured clones with exact electrical and mechanical compatibility. The choice between repair, emulation, or clone replacement depends on the required expertise, budget, and the criticality of the equipment.

FAQs

Q1: What does "LM64P101" stand for?A: It's a model number for a 128x64 pixel graphic LCD module designed by SHARP, with "LM" likely denoting LCD Module.

Q2: Can I use an LM64P101 with an Arduino?A: Not directly. It requires specific SHARP CPU drive signals. You would need a driver board or microcontroller to emulate the SHARP protocol.

Q3: What is the most common point of failure on these displays?A: The electroluminescent (EL) backlight often dims or fails first. The zebra strip connectors can also degrade, causing missing segments.

Q4: Is the LM64P101 compatible with all SHARP microcontrollers?A: No, only with specific series that have built-in LCD drivers, like the LH5160, LH5164, and LH5264.

Q5: How do I adjust the contrast on an LM64P101?A: Contrast is typically controlled by a negative voltage (VEE/VLCD) supplied by the host system, often via a potentiometer on the main board.

Q6: Can I replace the backlight with an LED?A: Yes, but it requires modifying the power supply circuit, as EL backlights require high-voltage AC, while LEDs need DC current limiting.

Q7: Where can I find the pinout diagram?A> Original SHARP datasheets are hard to find. Pinouts are often deduced from host system schematics or shared by community forums.

Q8: What is a "zebra strip" connector?A: It's a conductive elastomer that connects the LCD glass to the PCB, providing electrical contact via alternating conductive and insulating layers.

Q9: Are there any direct modern equivalents?A> There are no direct electronic equivalents from major manufacturers. Compatibility must be verified part-by-part with third-party clones.

Q10: Why is this display still relevant today?A> It is critical for maintaining expensive legacy industrial and medical equipment that is still functionally sound but relies on this proprietary display.

Conclusion

The LM64P101 LCD display is far more than a simple output device; it is a testament to an era of tightly integrated, proprietary electronic design. Its deep coupling with SHARP's microcontroller architecture presents a unique set of challenges and learning opportunities for those working with legacy technology. From understanding its memory-mapped communication to navigating the complexities of the aftermarket sourcing landscape, expertise in this component is a niche but valuable skill.

As the industry continues to grapple with the longevity of critical embedded systems, the lessons learned from components like the LM64P101 are invaluable. They highlight the importance of documentation, the challenges of vendor lock-in, and the innovative spirit required for sustainable repair. Whether through careful sourcing, protocol emulation, or custom replacement, ensuring the continued operation of these displays is key to preserving the functionality and value of the systems they serve, bridging the gap between past engineering and present-day maintenance needs.