- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- PCB

- Siemens

- Switch Sensor

- Näherungsschalter

- Temperaturregler

- Schutzrelais

- Fiber Optic Sensor

- Encoder

- Fan

- other

- Heidelberg

- MITSUBISHI

- FANUC

- Siemens adapter

- Fujitsu connector

- Der Aufsichtsrat

- Board

- Contactor

- Circuit

- Omron

- Relais.

- Motortreiber

- power supply

- Cable

- Transformator

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PANASONIC HMI Touch Panel

- KYOCERA HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

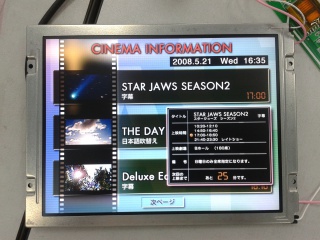

In the demanding world of industrial automation, medical equipment, and transportation systems, the display is far more than a simple output device—it is the critical interface between complex machinery and human operators. The choice of a display module directly impacts reliability, readability, and the overall success of an application. This article delves into the AA084SB01, an 8.4-inch LCD industrial screen with a resolution of 800 x 600 pixels (SVGA), to explore what makes it a preferred component for engineers and system integrators.

We will move beyond basic specifications to examine the core technologies, environmental resilience, and application-specific design considerations that define this display. From its underlying panel technology to its integration challenges and future-proofing potential, this analysis provides a comprehensive guide for professionals seeking a robust, high-performance visual solution for harsh or mission-critical environments.

Unpacking the Core Technology: The SVGA TFT-LCD Panel

At the heart of the AA084SB01 lies an 8.4-inch diagonal Thin-Film Transistor Liquid Crystal Display (TFT-LCD) panel with an SVGA (800 x 600) resolution. This resolution, while not considered high-definition by consumer standards, offers a distinct advantage in industrial contexts: pixel density and clarity are perfectly balanced for displaying complex control system graphics, diagnostic data, and textual information without requiring excessive processing power or high-bandwidth interfaces.

The TFT active-matrix technology ensures that each pixel is individually controlled, resulting in superior image stability, faster response times, and better color reproduction compared to passive matrix displays. This is crucial for displaying dynamic data or graphical user interfaces (GUIs) without ghosting or blur. The panel typically features a high-brightness backlight and a wide viewing angle, ensuring the screen remains legible from various positions—a key requirement in control panels or multi-operator environments

.

Built for Endurance: Ruggedized Design and Environmental Specifications

The defining characteristic of an industrial screen like the AA084SB01 is its ruggedness. Unlike consumer-grade monitors, it is engineered to perform reliably under strenuous conditions. Key specifications include an extended operating temperature range, often from -20°C to 70°C or wider, allowing deployment in unheated warehouses or under direct sunlight in vehicle cabins.

Furthermore, the module is designed to resist vibration and shock, critical for use in moving vehicles or on factory floors with heavy machinery. Many industrial displays also feature enhanced resistance to electromagnetic interference (EMI), ensuring signal integrity in electrically noisy environments. The construction typically involves robust materials and secure connectors to prevent failure from physical stress or corrosion, guaranteeing long-term operation where failure is not an option.

The Interface Backbone: LVDS and System Integration

The AA084SB01 commonly utilizes an LVDS (Low-Voltage Differential Signaling) interface. This is a pivotal feature for industrial integration. LVDS is a high-speed, low-power, low-noise digital interface standard that transmits data over differential pairs, making it highly resistant to common-mode noise. This ensures a clean, reliable signal transmission over longer cable lengths within a system chassis.

For system integrators, this means simplified and robust connectivity to a wide range of industrial single-board computers (SBCs), embedded systems, and controllers that support LVDS output. Understanding the pin configuration, power requirements (often a single +3.3V or +5V supply), and backlight control signals (typically PWM for dimming) is essential for a seamless and stable integration into the final product architecture.

Application-Specific Adaptations: Touch and Optical Bonding

To meet diverse user interface needs, the AA084SB01 platform is often available with optional enhancements. The most common is the integration of a resistive or projected capacitive (PCAP) touchscreen. A resistive touchscreen, operable with gloves or a stylus, is ideal for harsh environments. PCAP offers multi-touch capability and better clarity but may require bare fingers or specialized conductive gloves.

Another critical option is optical bonding. This process fills the air gap between the LCD panel and the cover glass or touch sensor with a clear resin. This technology dramatically reduces internal reflection, enhances sunlight readability, prevents condensation, and increases the structural durability of the display stack. For outdoor or high-humidity applications, optical bonding is often a necessary specification.

Optimizing for the Environment: Brightness, Contrast, and Readability

Selecting an industrial display requires careful analysis of the installation environment. The AA084SB01's high-brightness backlight, often measured at 500 nits or more, is essential for combating ambient light in sunlit factories or vehicle cockpits. A high contrast ratio ensures that graphics and text remain sharp and distinguishable.

Readability is further influenced by the choice of surface treatment. Displays may come with a glossy finish for vibrant color in controlled lighting or an anti-glare (matte) treatment to diffuse ambient light and reduce reflections. The decision hinges on the primary lighting conditions. Additionally, the color gamut and grayscale performance must be evaluated if the application involves detailed graphical data or medical imaging.

Lifecycle and Supply Chain Considerations for OEMs

For Original Equipment Manufacturers (OEMs), the commitment to a display module extends beyond technical specs. The long-term availability and lifecycle of the AA084SB01 are paramount, as industrial and medical products may remain in production for a decade or more. Reputable suppliers guarantee stable supply and avoid unannounced design changes that could force costly system requalification.

OEMs must also consider the total cost of integration, including driver board compatibility, mechanical mounting solutions, and the availability of technical support. Partnering with a supplier that provides comprehensive documentation, evaluation kits, and engineering support can significantly reduce development risk and time-to-market for the final product.

FAQs: LCD Display AA084SB01

1. What is the primary resolution of the AA084SB01 display?It features an SVGA resolution of 800 x 600 pixels.

2. What is the screen size measured diagonally?The screen size is 8.4 inches.

3. What type of interface does this display typically use?It commonly uses an LVDS (Low-Voltage Differential Signaling) digital interface.

4. Is this display suitable for outdoor use?With high-brightness backlighting, wide temperature range, and optional optical bonding, it can be configured for outdoor or high-ambient-light environments.

5. Does it support touch functionality?Touch is often an optional feature, with resistive or projected capacitive (PCAP) touchscreens available.

6. What is the advantage of optical bonding?Optical bonding improves sunlight readability, reduces condensation, enhances durability, and minimizes reflections.

7. What is a typical operating temperature range?Industrial displays like this often operate from -20°C to 70°C, but specific ranges should be verified with the datasheet.

8. Why is LVDS preferred in industrial settings?LVDS offers high-speed, low-power data transmission with high noise immunity, ideal for electrically noisy industrial environments.

9. Can this display be used in medical equipment?Yes, its reliability, stability, and potential for high contrast make it suitable for certain medical devices, subject to full system certification.

10. Where is this display commonly applied?Typical applications include industrial HMI, transportation systems, medical devices, test and measurement equipment, and point-of-sale terminals.

Conclusion

The AA084SB01 8.4-inch industrial LCD display exemplifies the engineering principles required for success beyond the consumer market. Its value is not defined by ultra-high resolution, but by a deliberate combination of robust SVGA clarity, exceptional environmental hardening, and reliable LVDS integration. As we have explored, its true worth is realized in its adaptability—through touch options, optical bonding, and careful specification for target environments—to meet the precise demands of challenging applications.

For engineers and procurement specialists, selecting such a component requires a holistic view that balances immediate technical needs with long-term supply chain stability. By understanding the depth of features and considerations surrounding modules like the AA084SB01, professionals can make informed decisions that ensure the longevity, reliability, and ultimate usability of their critical systems, where display performance is inextricably linked to operational success.