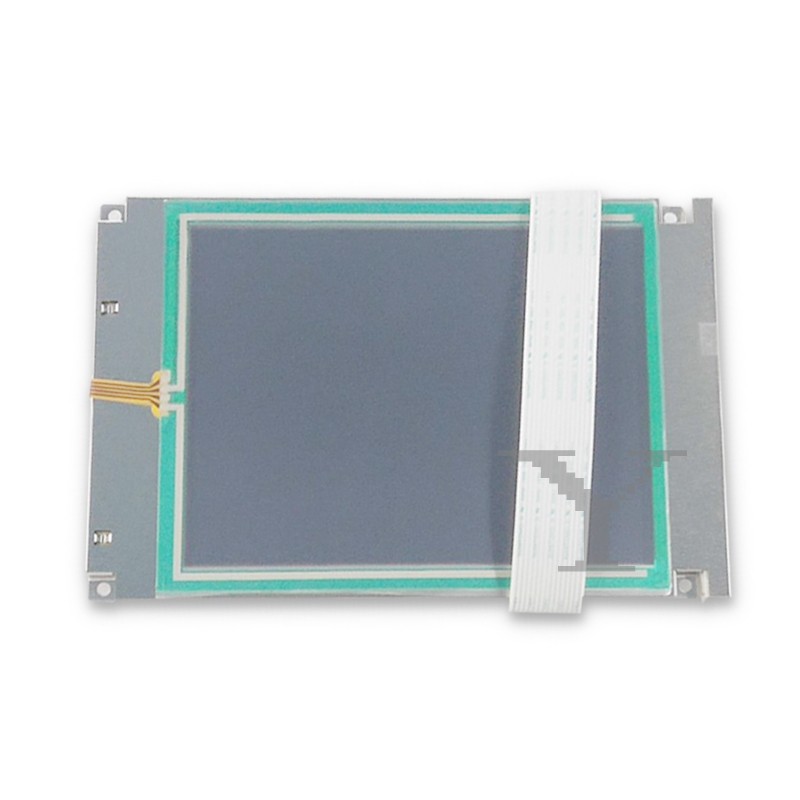

- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- PCB

- Siemens

- Switch Sensor

- Näherungsschalter

- Temperaturregler

- Schutzrelais

- Fiber Optic Sensor

- Encoder

- Fan

- other

- Heidelberg

- MITSUBISHI

- FANUC

- Siemens adapter

- Fujitsu connector

- Der Aufsichtsrat

- Board

- Contactor

- Circuit

- Omron

- Relais.

- Motortreiber

- power supply

- Cable

- Transformator

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PANASONIC HMI Touch Panel

- KYOCERA HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

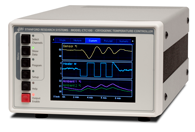

In the intricate world of industrial and commercial display solutions, the precise matching of a panel to its intended application is paramount. The SP14Q006 5.7-inch LCD display panel, designed specifically for integration with KOE (Kyocera Optec Electronics) display modules, represents a critical component in a vast ecosystem of human-machine interfaces. This article delves deep into the technical essence and application significance of this specialized panel. We will move beyond basic specifications to explore its role within the KOE framework, the engineering rationale behind its design choices, and the tangible impact it has on end-product performance. For engineers, procurement specialists, and product developers, understanding the nuances of such a component is not merely an exercise in sourcing but a fundamental step in ensuring system reliability, longevity, and optimal user interaction.

This exploration is particularly relevant as industries from medical instrumentation to industrial automation demand displays that are not just viewable, but robust, consistent, and perfectly synchronized with their control systems. The SP14Q006 serves as a prime case study in how a seemingly standard LCD panel is, in fact, a highly engineered solution tailored for demanding environments.

Decoding the SP14Q006: Core Specifications and KOE Integration

The SP14Q006 is a 5.7-inch diagonal TFT LCD panel with a resolution of 320 x 240 pixels (QVGA). This format, while considered modest by consumer standards, is a workhorse in industrial applications where clarity, reliability, and compatibility often outweigh sheer pixel density. Its integration path is specifically architected for KOE modules, meaning its physical interface, pinout, and electrical characteristics are designed to be a plug-and-play component within KOE's system-on-glass or controller-board ecosystems.

This seamless integration is the first layer of value. Engineers sourcing the SP14Q006 are not just buying a bare panel; they are acquiring a component guaranteed to interface correctly with the accompanying KOE driver logic and power supply. This reduces development risk, simplifies the bill of materials, and accelerates time-to-market. The panel typically features a standard RGB interface and operates on LVDS or other common industrial signaling protocols, ensuring data integrity and signal stability even in electrically noisy environments.

The Engineering Rationale: Why This Form Factor Endures

The persistence of the 5.7-inch QVGA format in industrial markets is not an accident of legacy but a result of deliberate engineering trade-offs. The screen size offers a substantial enough canvas to present complex data, menus, and schematics without dominating the device's front panel or incurring significant cost and power penalties. The QVGA resolution provides sufficient detail for alphanumeric readouts, basic graphics, and user interface elements while maintaining excellent character legibility.

From a system design perspective, this lower resolution reduces the load on the host processor and requires less memory bandwidth compared to higher-resolution displays. This allows for the use of more cost-effective microcontrollers and contributes to overall system power efficiency. Furthermore, the physical robustness of a smaller panel with a standard aspect ratio (4:3) makes it mechanically stable and easier to house securely, a critical factor for equipment subject to vibration or shock.

Critical Performance Parameters Beyond the Spec Sheet

While datasheets list brightness, contrast, and viewing angles, the true performance of the SP14Q006 in the field is defined by parameters often buried in notes or guaranteed by the manufacturer's pedigree. Operating temperature range is paramount; a true industrial panel must perform flawlessly from freezing cold to sweltering heat, often spanning -20°C to 70°C or wider. Backlight lifetime, usually measured in tens of thousands of hours, dictates maintenance cycles and product longevity.

Equally critical is optical bonding—an option where the LCD glass is laminated directly to the cover lens or touchscreen. This process eliminates an air gap, reducing internal reflection, enhancing contrast in bright ambient light, and providing superior resistance to condensation and physical shock. For the SP14Q006, availability in bonded or unbonded configurations allows designers to tailor the panel to the environmental demands of the final application, be it a factory floor or a medical cart.

Application Landscape: Where the SP14Q006 Excels

The specific attributes of the SP14Q006 make it a preferred choice in several key verticals. In industrial automation, it serves as the interface for PLCs, CNC machine controls, and test equipment, where its reliability and readability under factory lighting are essential. The medical device field utilizes it in portable diagnostic units, patient monitors, and laboratory analyzers, valuing its consistent performance and potential for medical-grade certifications

Additionally, it finds a home in transportation and logistics (e.g., forklift dashboards, tracking devices), point-of-sale systems, and embedded instrumentation. In each case, the panel is not a consumer-facing feature but an integral, mission-critical component of a larger system. Its failure means the failure of the device's primary user interface, underscoring the importance of sourcing from reliable supply chains and understanding its lifecycle status.

Supply Chain and Lifecycle Considerations

For a component like the SP14Q006, designed for products with multi-year or even decade-long lifecycles, supply chain stability is as important as technical specification. KOE, as a manufacturer, typically provides long-term support for its modules and compatible panels. However, proactive lifecycle management is crucial for OEMs.

This involves monitoring the panel's production status (active, end-of-life, obsolete), securing last-time buys before discontinuation, and evaluating form-fit-function replacements. A deep understanding of the SP14Q006's exact driving scheme and mechanical dimensions allows for smoother future transitions. Partnering with distributors who specialize in industrial displays and offer component obsolescence management services becomes a strategic advantage, mitigating the risk of production halts.

The Future Context: Niche Panels in an Evolving Market

As consumer technology drives toward larger, higher-resolution, and cheaper panels, the market for specialized industrial displays like the SP14Q006 evolves differently. The trend is not necessarily toward obsolescence but toward consolidation and customization. While the fundamental QVGA 5.7-inch format may remain, advancements come in the form of improved LED backlights for higher efficiency and longer life, enhanced optical characteristics, and more integrated touch solutions (resistive, capacitive).

The future of this panel lies in its continued adaptation to modern requirements while maintaining backward compatibility and reliability. It may serve as a bridge technology, with its interface being emulated on newer display cores to extend the life of legacy systems. Its value proposition will increasingly hinge on its certification for specific environments, extended temperature performance, and guaranteed supply—factors that transcend simple pixel count.

FAQs: SP14Q006 5.7" LCD Display Panel

1. What is the SP14Q006?A 5.7-inch QVGA TFT LCD panel designed for seamless integration with KOE display modules.

2. What is its primary resolution and interface?It has a resolution of 320 x 240 pixels and typically uses an RGB/LVDS interface compatible with KOE controllers.

3. Why choose a 5.7" QVGA panel today?For industrial reliability, lower system cost/power, excellent legibility, and compatibility with legacy and current embedded systems.

4. What does "for KOE" specifically mean?It means the panel's physical, electrical, and timing characteristics are designed to work plug-and-play with KOE's driver electronics and system architecture.

5. What is optical bonding and why is it important?It laminates the LCD to the cover glass, improving readability in sunlight, durability, and sealing against moisture/dust.

6. What are typical applications?Industrial HMIs, medical devices, POS systems, transportation dashboards, and test/measurement equipment.

7. What is a critical non-visual specification?The wide operating temperature range (e.g., -20°C to 70°C), essential for harsh environments.

8. How do I manage its product lifecycle?Monitor its status with KOE/distributors, plan for last-time buys, and identify compatible replacements early.

9. Can it be used with a touchscreen?Yes, it is commonly paired with resistive or projected capacitive touchscreens, often in an optically bonded assembly.

10. Is it being phased out by higher-res displays?Not directly. It serves a specific niche where its balance of size, cost, reliability, and system simplicity remains optimal.

The SP14Q006 5.7-inch LCD panel exemplifies the enduring importance of purpose-engineered components in a world often dazzled by consumer-grade specs. Its value is not defined by megapixels but by its seamless integration within the KOE ecosystem, its robust performance under duress, and its critical role in the functionality of countless industrial and medical systems. Understanding this panel requires looking beyond the glass surface to the engineering decisions that ensure longevity, stability, and clarity in demanding applications.

For designers and specifiers, the key takeaway is that selecting such a display is a strategic decision. It involves balancing immediate technical needs with long-term supply chain viability, all while ensuring the component enhances the reliability and user experience of the final product. The SP14Q006, and panels like it, remain the silent, reliable workhorses of the embedded world, proving that in specialized technology, optimal fit often trumps raw specification.