- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- PCB

- Siemens

- Switch Sensor

- Näherungsschalter

- Temperaturregler

- Schutzrelais

- Fiber Optic Sensor

- Encoder

- Fan

- other

- Heidelberg

- MITSUBISHI

- FANUC

- Siemens adapter

- Fujitsu connector

- Der Aufsichtsrat

- Board

- Contactor

- Circuit

- Omron

- Relais.

- Motortreiber

- power supply

- Cable

- Transformator

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PANASONIC HMI Touch Panel

- KYOCERA HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

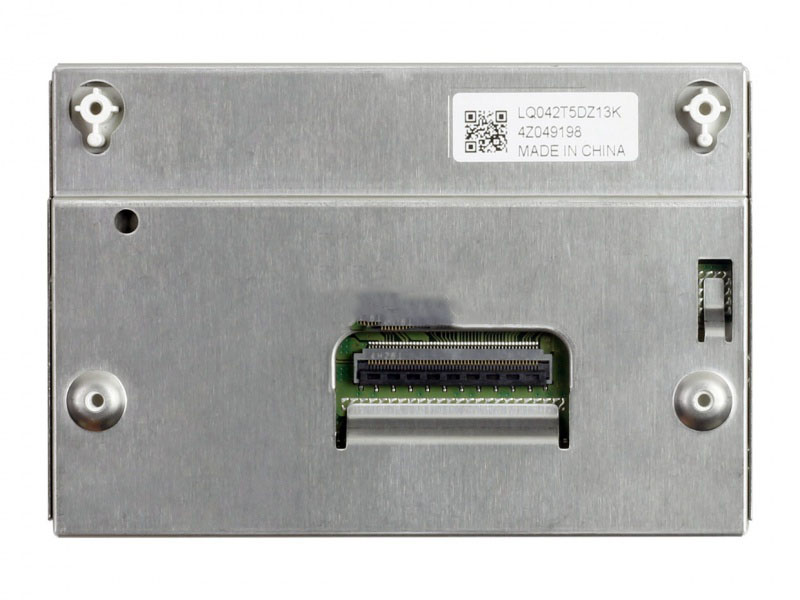

In the intricate world of embedded systems and custom electronics, the display often serves as the critical bridge between machine and user. Among the myriad of options available to engineers and product developers, the LQ042T5DZ13K 4.2-inch LCD display module stands out as a sophisticated and highly integrated solution. This module is far more than a simple screen; it is a complete, self-contained display system engineered for performance and reliability in demanding applications.

This article delves into a comprehensive technical and practical analysis of the LQ042T5DZ13K. We will move beyond basic datasheet specifications to explore its architectural advantages, the nuances of its driver integration, and its ideal application environments. Our goal is to provide design engineers, product managers, and technology enthusiasts with a deep understanding of why this specific module might be the optimal choice for their next project, examining the factors that influence integration complexity, performance outcomes, and long-term viability in the market.

Core Architecture and Integrated Design Philosophy

The key to its streamlined integration is the onboard RA8875 display controller. This powerful IC handles all low-level timing, power sequencing, and pixel management, presenting a simpler parallel or SPI interface to the host microcontroller or processor. This architecture absolves the main system CPU from memory-intensive bitmap manipulation and complex timing generation, significantly reducing firmware development time and system resource consumption. The module's design represents a shift from component-level assembly to a subsystem approach, accelerating time-to-market.

Electrical Interface and Signal Integration

The data interface commonly utilizes an 8-bit or 16-bit parallel bus, along with essential control signals (WR, RD, RS, CS). This parallel communication ensures high-speed data transfer for smooth graphics rendering. For systems with limited GPIOs, the module often supports a 4-wire SPI mode, trading some speed for pin count efficiency. Designers must meticulously follow the timing diagrams in the datasheet, ensuring signal integrity through proper impedance matching and length matching for parallel data lines in high-speed or noise-sensitive environments.

Optical Performance and Viewing Characteristics

Critical optical parameters include its viewing angle, specified using the standard 6 o'clock or 12 o'clock direction. Modern TFTs like this one offer wide viewing angles (often 70/70/50/70 degrees in Left/Right/Up/Down), ensuring the image remains consistent for viewers not directly in front of the screen. The selection of the polarizer and surface treatment (glare, anti-glare, or optically bonded) further defines its performance under direct light, a key consideration for industrial or automotive applications.

Firmware Driver Development and Abstraction

The strategic approach is to develop or acquire a hardware abstraction layer (HAL). This layer wraps all low-level register writes and reads into higher-level functions (e.g., `Draw_Button()`, `Update_Gauge()`). Such abstraction makes the application code portable and readable. Furthermore, leveraging the controller's internal display list or 2D graphics accelerator can offload animation or complex UI rendering from the host MCU, enabling smoother performance on less powerful hardware.

Application-Specific Considerations and Environments

The LQ042T5DZ13K finds its niche in applications where reliability, compact integration, and a balanced screen size are critical. It is a favored choice for industrial human-machine interfaces (HMIs) on control panels, portable diagnostic equipment, and embedded instrumentation. Its self-contained nature provides resilience against electrical noise common in factory settings.

In the automotive aftermarket and consumer electronics realms, it serves as the display for advanced car audio head units, navigation devices, and smart home controllers. For each environment, additional design factors come into play: operating temperature range (ensuring performance from -20°C to 70°C or beyond), mechanical mounting strategy to resist vibration, and potential need for enhanced optical bonding to mitigate condensation or improve sunlight readability.

Comparative Analysis and Market Positioning

Its primary competition comes from other integrated TFT modules. Its advantages often lie in the specific performance of the RA8875 controller, the quality and consistency of the LCD glass, and the manufacturer's reliability and support. For projects requiring a ready-to-use, medium-sized display with excellent graphics support, the LQ042T5DZ13K presents a compelling, de-risked solution that balances capability with developer accessibility.

FAQs: LQ042T5DZ13K 4.2" LCD Display Module