- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- PCB

- Siemens

- Switch Sensor

- Näherungsschalter

- Temperaturregler

- Schutzrelais

- Fiber Optic Sensor

- Encoder

- Fan

- other

- Heidelberg

- MITSUBISHI

- FANUC

- Siemens adapter

- Fujitsu connector

- Der Aufsichtsrat

- Board

- Contactor

- Circuit

- Omron

- Relais.

- Motortreiber

- power supply

- Cable

- Transformator

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PANASONIC HMI Touch Panel

- KYOCERA HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

In the intricate world of industrial and embedded display solutions, the precise matching of a display module to its controller board is paramount for optimal performance and reliability. The SP14Q005 5.7-inch display module, designed explicitly for use with KOE (Kyocera Display's Original Equipment) interface controllers, represents a specialized component in this ecosystem. This article delves into the technical nuances, application contexts, and strategic advantages of this specific display solution.

Moving beyond a simple product specification sheet, we will explore why the SP14Q005 is more than just a screen; it is a carefully engineered subsystem. Its integration with KOE's established controller architecture offers designers a path to reduced development risk and accelerated time-to-market. From its core characteristics to its role in demanding industrial environments, this deep dive aims to provide engineers, procurement specialists, and technology integrators with a comprehensive understanding of where and how the SP14Q005 module creates definitive value.

Understanding the KOE Ecosystem and Display Integration

Integration becomes a plug-and-play exercise rather than a complex engineering challenge. The KOE standard ensures that the controller sends pixel data in a format and sequence that the display module's driver IC expects. This seamless compatibility reduces hardware design iterations, minimizes potential for signal integrity issues, and allows developers to focus their resources on application software and user interface design, rather than low-level display driving complexities.

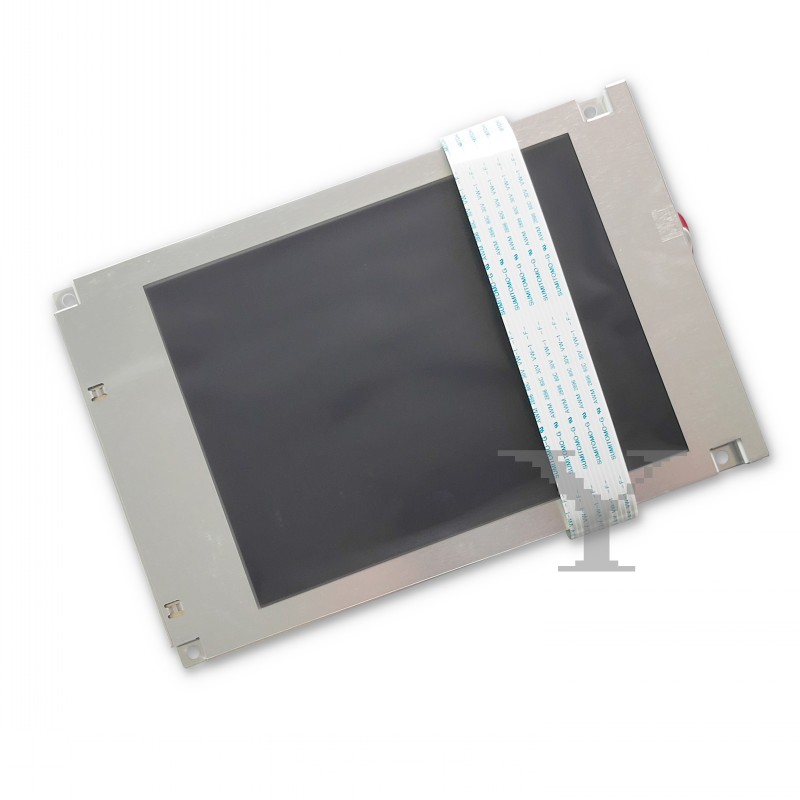

Technical Specifications and Performance Profile of the SP14Q005

Key performance parameters include its brightness, measured in nits, which determines readability in various ambient lighting conditions, and its contrast ratio. The viewing angle, often specified using the IPS (In-Plane Switching) or similar wide-view technology, is critical for applications where the screen may not be viewed head-on. Furthermore, the module's operating temperature range, often industrial-grade (e.g., -30°C to +80°C), is a defining feature, distinguishing it from commercial-grade displays and underscoring its suitability for harsh environments.

Design Advantages for Embedded and Industrial Systems

From a mechanical standpoint, these modules are designed as drop-in units, often featuring a robust metal frame that provides structural integrity and aids in electromagnetic interference (EMI) shielding. This built-in ruggedness is essential for industrial settings where equipment is subject to shock, vibration, and electrical noise. The predictable physical and electrical footprint also simplifies enclosure design, thermal management planning, and overall system architecture.

Critical Application Sectors and Use Cases

Other significant applications include medical devices (where consistent performance is critical), transportation systems (for in-vehicle information displays or control panels in rugged vehicles), and test and measurement equipment. In each case, the module's ability to deliver stable performance over a wide temperature range and its resistance to environmental stressors make it a preferred choice over consumer-grade alternatives. Its QVGA resolution is often perfectly suited for displaying schematic diagrams, status menus, and data readouts without unnecessary graphical complexity.

Integration Considerations and Potential Challenges

Another consideration is the end-of-life (EOL) management of components. While the standardized interface offers some protection, it is vital to have a sourcing strategy or approved alternate modules from the supplier. Furthermore, for ultra-long-lifecycle products, understanding the longevity of the backlight and the availability of replacement modules years into the future is a key part of the design decision.

Future Trajectory and Compatibility with Modern Interfaces

The future for modules like the SP14Q005 lies in their continued role in legacy support and niche industrial applications where changing an established, reliable architecture carries more risk than benefit. Manufacturers often bridge this gap by offering modern TFT panels with a built-in KOE-compatible timing controller (TCON), thus extending the life of this interface standard. The key for integrators is to evaluate the total cost of ownership, including design effort, against the specific performance needs of their application.

Frequently Asked Questions (FAQs)

Q10: Is the KOE interface becoming obsolete?A> While newer serial interfaces are emerging, the KOE standard remains widely used and supported, especially in industrial and embedded markets where design stability is valued over cutting-edge specs.